Contact

-

Chad Butson

-

126 Smiths Way RD3, \n Cromwell 9383

- chadbutson@gmail.com

- https://www.dunfordgrove.com

- https://www.facebook.com/profile.php?id=100063685174315&fref=ts

- https://www.instagram.com/dunfordgrove/

-

Added Value Olive Oil Shop online & deliveries Seasonal Vendor

Dunford Grove

We’re Jess and Chad. In April 2025, we became the proud new caretakers of Dunford Grove. Our vision is simple: to continue crafting the highest-quality, spray-free olives and hazelnuts while caring for the land that makes it all possible.

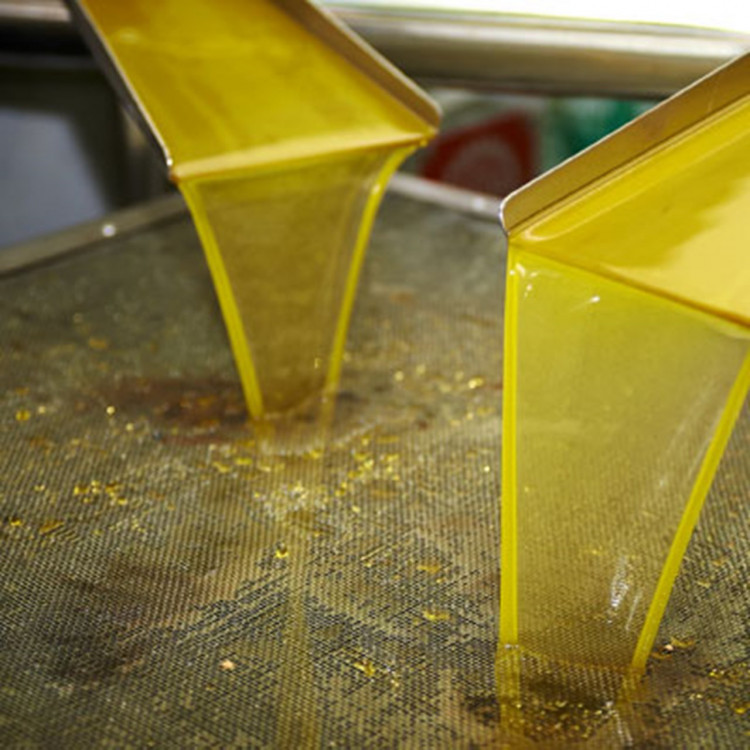

Tucked beside the sparkling shores of Lake Dunstan, our grove is home to over 1,000 Tuscan olive trees—Leccino, Frantoio, and Pendolino. Central Otago’s dramatic climate, with its hot dry summers and crisp winters, might be tough on us, but it’s perfect for growing healthy, disease-free trees and producing extra virgin olive oil with a truly unique character. Alongside the olives, 400 hazelnut trees add richness and variety to the harvest.

We are at the Otago Farmers Market every first Saturday of the month. We can’t wait to share a taste of our award-winning olive oil with you.